5 common application problems with concrete sealer - and how to avoid them

Some jobs are simple, easy, and straightforward and we finish them on schedule.

Then there are others that start out as easy, but soon become costly and time-consuming due to badly applied concrete sealant. To avoid this, here are some common application issues to be aware of, and what you can do to make sure that you avoid them.

In this blog post, we will be talking about interior and exterior sealants. Both are equally important to install and maintain.

1. Sealant Bubbles

Bubbling could happen when the sealer is either applied too thickly or if the exterior sealant was applied during the hottest part of the day and/or in the direct sun. The ideal thickness of your concrete sealant should be no more than 5-6 MIL. When sealer is applied too heavily, air bubbles can’t rise to the surface and escape. As an example, 2 thin layers should be applied instead of one thick layer.

Apply sealer during the early or later parts of the day when the weather is cooler to avoid bubbles. If the sealant gets too hot, it will form a skin on the top layer, trapping solvent inside. Normally, the solvent will evaporate as the sealer dries. If the sealant cannot release the solvent, it will create bubbles in the sealant.

2. Dark, patchy concrete after sealer application

Most acrylic sealers will deepen the color of concrete and leave a partly glossy finish. Sealers will bring out the grain or texture in concrete the same way wood varnish does the grain in wood. To eliminate this, you can try using a penetrating sealer or do a test application of the sealer on a small area first to check for any unwanted color changes.

3. Sealer is stained from factors like oil, leaves, and/or tires

For more durability and stain resistance try an epoxy or urethane coating system. Always check its functionality for exterior use before applying. Pentra-Guard (EXT) resists stains and dusting and makes concrete much easier to maintain. It’s also compatible with integrally colored concrete, stains, and dyes. We also carry many interior sealants; call to see which product is right for you.

4. Water-based sealer is white and powdery

The drying process of water-based sealers is significantly affected by the weather. Always check what temperatures and humidity levels are best for application before starting your sealing project.

5. Solvent-based sealer turned white and is peeling and flaky

The first problem could be that the exterior sealant was applied to concrete that was either wet or too ‘fresh’ and still contained bleed water. When this happens the sealer will not naturally stick to the concrete surface but rather float or trap a thin film of water. The second problem could be that your application might have been too thickly applied. Too many coats of sealer or even a build-up of sealer over a number of years could trap moisture under the sealer and cause it to lose its grip on the concrete.

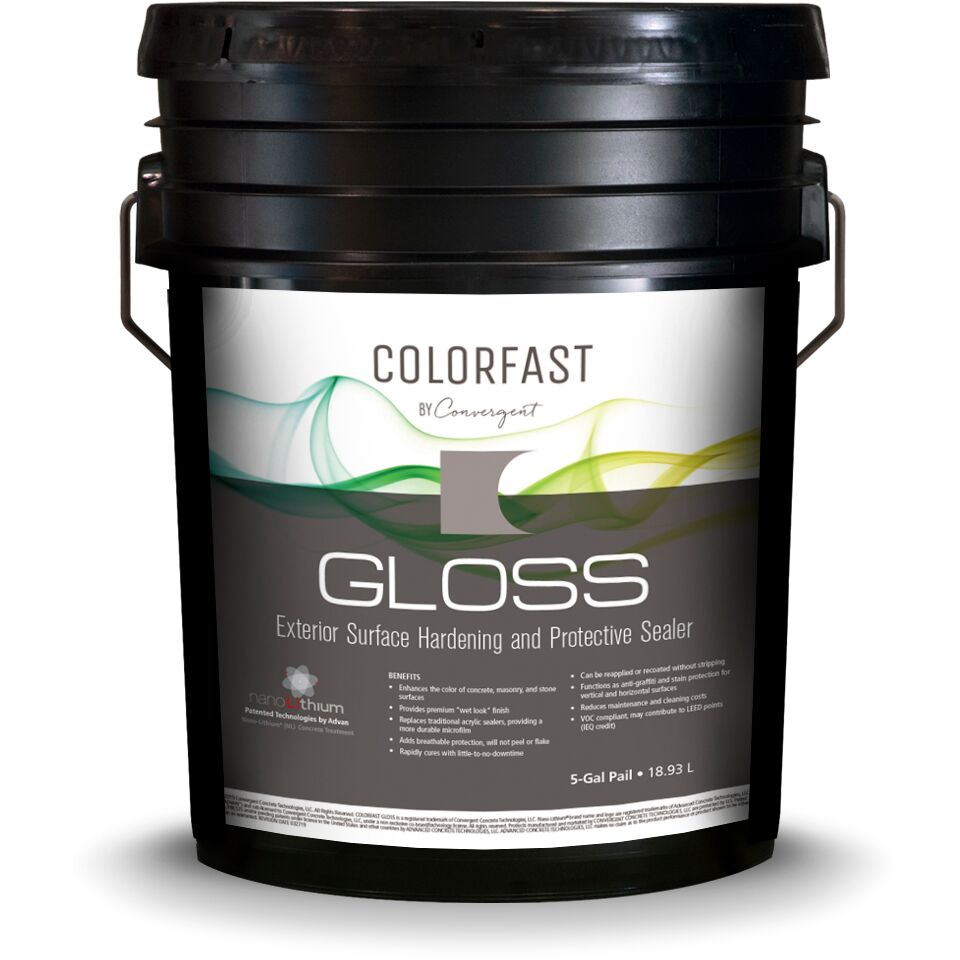

Easy to apply, quick-curing concrete sealer

Pentra-Finish (HG) is fast-drying, high-gloss lithium sealer. This product is a great solution for colored and stained concrete. Pentra-Finish (HG) increases shine, enhances color, and improves resistance against abrasion and stain. Call us today to see if this, or any of our many products is the right fit for you.

Call us at 801-375-2280 or visit www.convergentconcrete.com