Concrete sealing–Repair microcracking and imperfections first

Sealing and filling micro-cracks and imperfections on your concrete floor will not only prolong the life of your floor but also improve it aesthetically. The key to the successful application of your concrete sealer or filler lies in the careful and proper preparation of the surface. A specific CSP (concrete surface profile) may be required for a particular product. A CSP is a standardized measure for how rough the surface is and it’s defined by the International Concrete Repair Institute (ICRI). A very rough surface will have a high CSP number and a virtually smooth surface with little preparation will be the lowest, at a CSP 1.

|

CSP 1 |

Acid etching |

|

CSP 2 |

Grinding |

|

CSP 3 |

Light shotblast |

|

CSP 4 |

Light scarification |

|

CSP 5 |

Medium shotblast |

|

CSP 6 |

Medium Scarification |

|

CSP 7 |

Heavy Abrasive blast |

|

CSP 8 |

Scabbling |

|

CSP 9 |

Heavy scarification or milling |

To properly prepare your surface before application, the most important thing you can do is to check if the substrate can absorb water adequately. Porosity is key. This is easy to check by pouring water on the surface and waiting to see if it is absorbed. If it is able to absorb water it will be able to properly absorb your penetrating sealer too.

These coatings don’t require the concrete to be as porous as it would be necessary for penetrating sealers. They do however require a significantly rough surface to optimize adhesion. A solvent-based acrylic sealer will enhance the color of your floor and bond relatively easily with any leftover resin from previous applications. A water-based acrylic coating on the other hand will not enhance the color much and will require a clean, dry, and preferably lightly sanded surface for optimal adhesion.

Topical sealants like epoxy and urethane require similar preparation of the surface as acrylic sealers do, but are less breathable than acrylic sealers so moisture transmission might need to be accounted for. It is also a good idea to check for any underlying moisture and to sort this out before applying a topical sealant.

Grinding is necessary. Micro-crack fillers like Pentra PCF are reactive treatments that are applied during the grinding process, as it mixes with the dust that is created while grinding. It easily fills small holes, cracks, and imperfections in your concrete surface and adds to the durability and longevity of your concrete floor.

Concrete micro-crack sealer–Repairing and protecting commercial and industrial concrete flooring

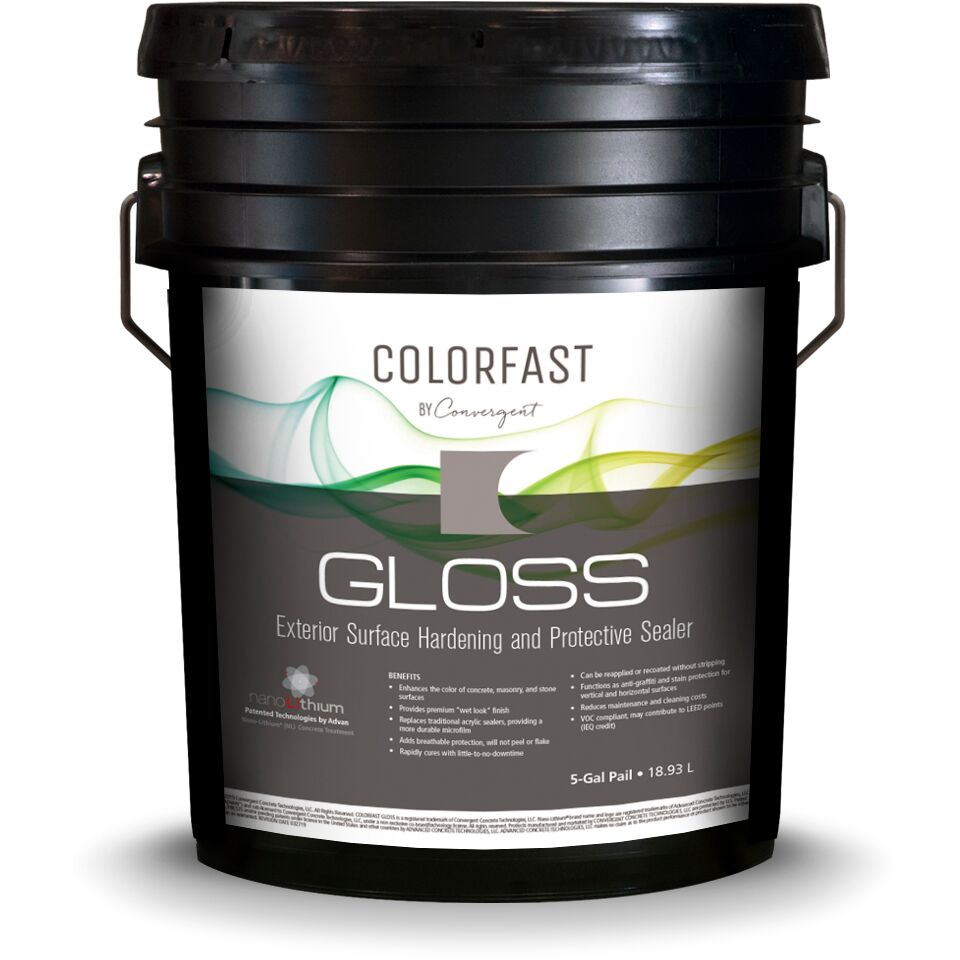

Pentra PCF is our recommendation for microcracking and pinhole filling to insulate and create a polished and durable surface that’s easier to maintain and that looks glossy and beautifully reflective. Ask the experts at Convergent Concrete Technology to solve all your concrete floor sealing and concrete floor filler needs.