Lithium Densifiers FAQ’S: Part 1

Lithium silicates are an intense chemical hardener for concrete flooring. They have become increasingly popular for diamond polished floor work– more so than their sodium and potassium silicate counterparts. Lithium silicates have a smaller molecular structure and are almost like ‘liquid glass’, working hard at filling tiny pores and irregularities in your concrete surface as well as penetrating deeper than other silicates. This strengthens and increases the surface density of your concrete and leaves you with a durable surface.

Newly laid concrete has excess moisture that needs to evaporate during the curing process. It could take up to a month before your concrete is solid and ready to be sealed. If you were to hastily apply a sealer before it has sufficiently cured, it could create a barrier and thus trap excess moisture inside. This would compromise the strength of your concrete and make it more prone to cracking and pitting.

You can pour concrete over dirt but some preparation is needed first to ensure the integrity of your concrete structure.

Yes, spraying is a popular way to apply a sealer to concrete. Alternatively, one can use a roller. Yes, when applying a lithium densifier, spraying the surface with the product is the correct application method. Allow the floor to be wet with the product for 20 minutes and then let dry.

The polishing process can take upwards of 2 to 3 days and depends on the size of the area and also the level of polishing that is needed.

Concrete densifying is absolutely necessary to protect your concrete from water absorption and surface abrasion. Densified concrete is much more resistant to cracking, spalling, and pitting. Densifying your concrete will make it more durable and it will last so much longer.

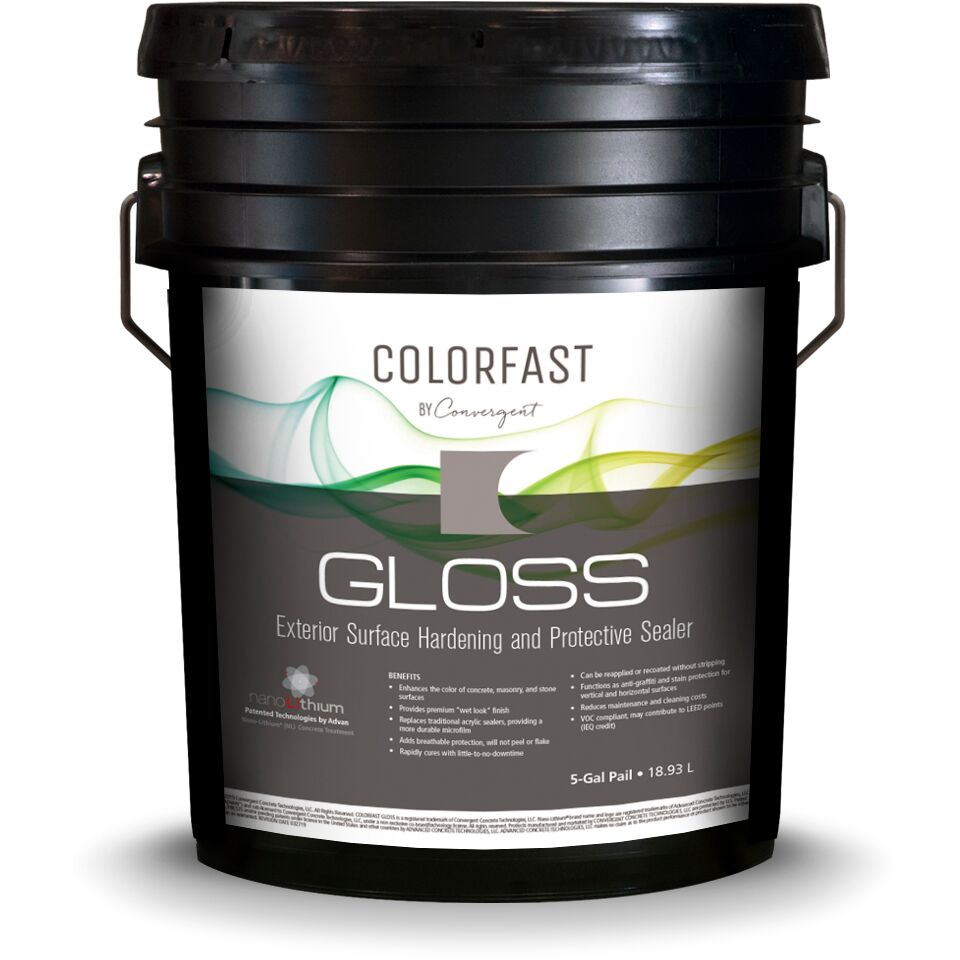

At Convergent Concrete we strive to bring you the very best technology and the most innovative products. Our patented technologies are unrivaled–so contact our team today to find out which products from our high-end range best suit your needs.