You Too Can Have Polished Concrete

Polished concrete is an ideal floor for a variety of settings, from industrial and manufacturing to office space, retail, institutional and even residential homes. It’s sustainable, cost-effective, durable and highly customizable. And perhaps the greatest benefit of this surface treatment is how easy it is to keep clean. Polished concrete is naturally low maintenance. It’s also breathable so moisture transmission problems are minimized.

Get a Beautiful Polished Concrete Floor

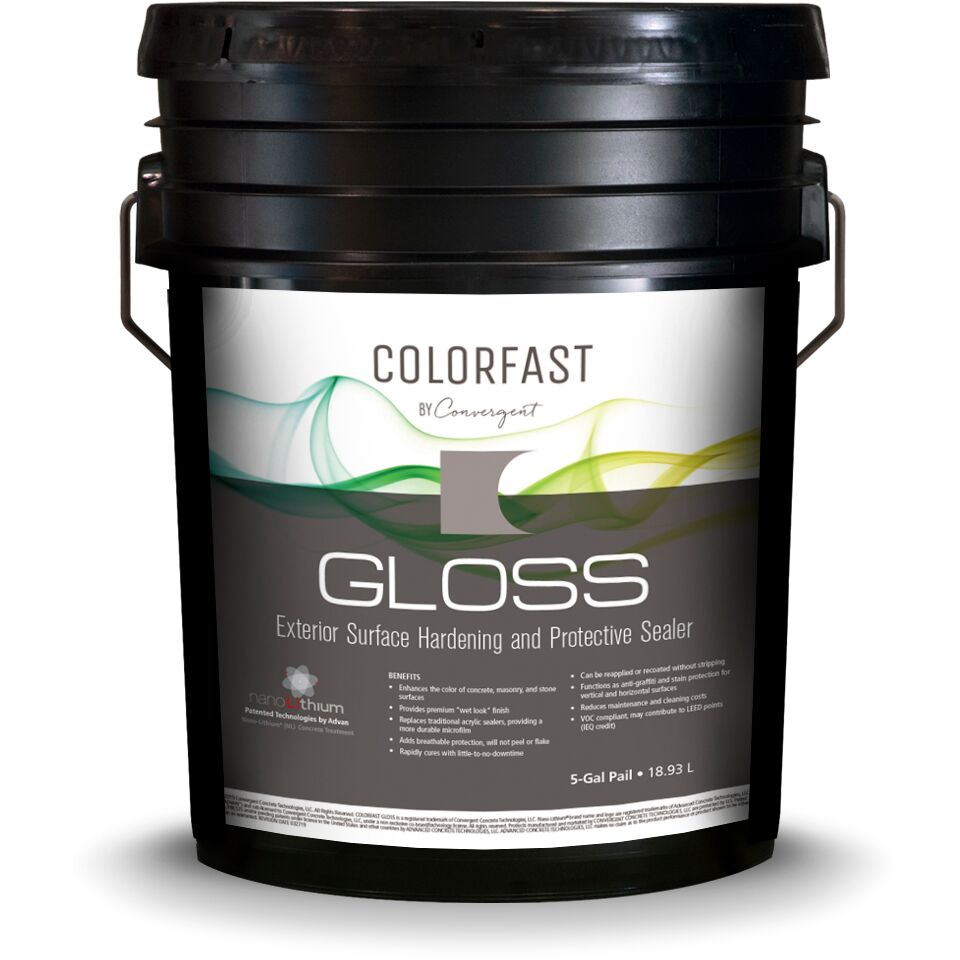

You can achieve a polished concrete floor whether you’re installing a new slab or restoring an existing concrete floor. Depending on the condition of the concrete, old floors may need cutting, sanding, or a new layer of thin concrete applied. Because concrete is porous, a densifier is then applied to harden and prepare for polishing. Diamond tooling is used to repeatedly grind the surface of the concrete while increasing refinement, resulting in a concrete floor that’s beautifully polished. For best results and longevity, a concrete floor sealer is applied.

Concrete surfaces can be polished to varying degrees, from a satin look to a mirror-like finish, and it all depends on the polishing process and grit number. Diamond polishing discs are described by grit number, and the grit can range from 30-3,000. The higher the grit number, the higher the polish, and the more reflective the finish. If a lower shine is desired, finish with a lower grit.

Choosing a wet versus dry polishing process can also help determine the final look of your concrete floor. In the wet polishing process, water is applied to the floor while polishing. This eliminates hazardous dust that is generated but does leave behind a slurry which needs to be cleaned up after polishing. Dry polishing dust is vacuumed up as part of the polishing process. Dry polishing can save time by eliminating the need to clean up slurry.

Get a Custom Look with Concrete Finishes

Polished concrete gives you the flexibility to choose many different styles to make your concrete floor more visually appealing. Depending on the depth of the concrete grinding, you can choose a light grind that gives a salt and pepper look or a more aggressive grind to expose larger aggregate.

Stains and dyes are often used as part of the polishing process to create customized decorative concrete floors that are also easy to clean. Stains and dyes come in an array of colors. A single color can be applied across the surface or specialty designs like logos or stencils can be applied.

How to Keep Your Polished Concrete Floor Looking Good

A polished concrete floor already provides a strong surface that minimizes damage and abrasion because of the densifier that was applied as part of the polishing process. Concrete polished floors are low maintenance and require no waxing or stripping to maintain cleanliness and shine.

To keep a polished concrete floor looking like new, sweep and dust it regularly to remove any accumulated dust or grit that could scratch it. Auto-scrub the floor with warm, soapy water regularly. For a higher-performance clean, choose a specialty cleaner like Pentra-Clean™ (DC) Daily Cleaner to avoid any soapy residue left behind. Obtain a deeper clean with Pentra-Clean™ (CR) for high-traffic and commercial flooring systems. Not only does it lift dirt and grime but it also protects the polish and restores the shine with Nano-Lithium technology. DO NOT USE cleaners that are acidic or that have citrus (d-Limonene) or Butyl compounds.

A polished concrete floor is a worthwhile investment for your commercial, industrial and residential needs. Call Convergent Concrete today to discuss which concrete flooring style best suits your project.

Call: (801) 375-2280

Email: info@convergentconcrete.com